Mayku’s guide to pressure forming technology, types, applications, materials, and more

In our previous article, we covered the basics of thermoforming and Mayku’s approaches to the technology with pressure forming and vacuum forming. Here, we’ll take a closer look at pressure forming, its benefits, applications, and more.

What is pressure forming?

Pressure forming refers to the process of using air pressure on a heated plastic sheet to create a mold or part that can exhibit high degrees of detail and texture.

Pressure forming is an enhanced version of vacuum forming. Using the process, the maximum pressure exerted is up to four times higher than vacuum forming.

How does pressure forming work?

First, a plastic sheet is inserted into a pressure-forming machine, so that it sits over a template. It is then heated. Once the proper temperature is reached, up to five tons of pressurized air pushes the plastic sheet over the template, then holds it under high pressure. An air vent removes any excess air. Once sufficiently cooled and hardened, the plastic – now a mold, or a final part after post-processing – is removed from the template to be used as is or to be further processed.

Templates used for pressure forming

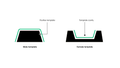

During the pressure forming process, tools called templates are used to create molds or parts. These templates can be male (also referred to as “positive”) or female (“negative”).

A male template is convex. When a heated plastic sheet is placed on it, the male template will help form the inner dimensions of the object. A female template is concave, guaranteeing dimensional accuracy on the exterior of the part created, because the plastic sheet is formed inside the template.

In pressure forming, female molds are often used, as parts with high levels of detail, texture or other exterior aesthetics are commonly created. For more on the differences between vacuum forming and pressure forming, you can read our articles on the basics of thermoforming and vacuum forming.

Benefits of pressure forming

Pressure forming offers manufacturers and end users a wide range of benefits. Among them:

- Aesthetics. The exteriors of pressure-formed parts or molds can be identical to those created with injection molding, meaning applications with textures, lettering, branding, text, or fine details work well with the pressure forming process.

- Part tolerances. Using a female template results in parts that adhere exactly to its dimensions – and exhibit excellent tolerances – making pressure-formed parts a good choice for assemblies.

- Affordability. Pressure forming rivals injection molding in terms of final product, but can often be achieved more cheaply, thanks to pressure forming’s lower tooling cost.

- Speed. The pressure forming process – including design, template manufacturing, and prototyping – is often faster than injection molding or other manufacturing processes.

- Cost-efficacy. In addition to a relatively low tooling cost, pressure forming is a good choice for creating small- to medium-batch runs of products.

Pressure forming applications

Below are a few of the most common applications that can be created with pressure forming.

- Packaging. Consumer, medical, and pharmacological products packaged in durable plastic are often created with pressure forming.

- Consumer products. Such as device covers, packaging and trays.

- Dental. Including tooth aligners, mouthguards, and other

- Automotive. Including dash fascias, plastic panels, and other small (predominantly interior) components.

- Aerospace. Such as drone cases and covers, lightweight covers to protect sensitive components.

- Industrial. Large format moldings, covers, and containers used to hold or protect equipment or tools used in industrial environments.

Learn more: Thermoforming applications: A practical guide

Pressure forming materials

Another benefit of thermoforming is its ability to be used in conjunction with a wide variety of materials that offer different mechanical properties. A few of the materials used in pressure forming include:

- PETG. Exhibiting good hardness, chemical resistance, impact resistance, transparency and ductility make PETG a good candidate for food-grade tools or parts. It’s also a material offered by Mayku.

- HIPS. Stable, low cost, and impact resistant qualities make HIPS well-suited to thermoforming – and is one of the materials offered by Mayku for our 3D formers.

- EVA. Another material offered by Mayku, with low-temperature toughness and UV resistance.

- Acrylic (PMMA). Transparent and with high impact and chemical resistance, acrylic is often used for protective equipment such as draft shields.

- UHMW. Incredibly durable and resilient form of polyethylene. Resistant to wear and tear and can outperform traditional steel components in some cases.

- ABS. Common material known for strength, impact and heat resistance, and rigidity.

- PC. Durable, UV-resistant, and lightweight, PC is an excellent material choice for machinery parts and lighting fixtures, such as skylights.

- PP. PP is a popular thermoforming material due to its desirable characteristics, such as heat, chemical, and fatigue resistance, as well as its cost-effectiveness.

- LDPE. LDPE is a chemical-resistant material with high strength and slight flexibility.

- HDPE. HDPE offers similar properties as LDPE, but it has increased density and more resistance to stress cracking.

- Cellulose acetate butyrate. Tougher than cellulose acetate, with low moisture absorption, with good transparency and weathering resistance. Can be used to coat metal and wood – or to create steering wheels, blister packaging, or pens.

- Cellulose acetate. Easy to use, highly durable, and flexible. Often used to create eyeglasses.

- PVC. Chemical-resistant, strong, rigid, and flame-retardant properties.

- Polystyrene. Stable, a great insulator, water-resistant, and lightweight, polystyrene is a solid choice for industrial construction and consumer goods.

Learn more: Thermoforming materials: A comprehensive guide

Vacuum forming vs. pressure forming

Pressure forming is similar to vacuum forming. But whereas vacuum forming uses a vacuum, the process of pressure forming applies up to five tons of pressure to a plastic sheet placed on a template. Because pressure levels are much higher than in vacuum forming, users can leverage pressure forming to achieve higher levels of detail in the parts they create – or use thicker materials for more professional applications. Vacuum forming, meanwhile, is more suited to objects created with thinner plastic – such as product packaging – that require less detail or textured surfaces.

If you’d like to learn more about the differences between pressure forming and vacuum forming, you can read our official comparison: Vacuum forming vs. pressure forming.

Mayku Multiplier: benchtop pressure forming machine

The Mayku Multiplier is a benchtop 3D former powered by industrial pressure forming technology. It’s compatible with multiple plastic types and thicknesses, and results in highly detailed final parts and molds. When filled with compressed air, the Multiplier’s dome exerts up to five tones of force. This pressure forces air onto a heated plastic sheet into every crevice of a mold, and can capture details of less than <1μm with materials such as EVA sheets.

Get started with thermoforming

Want to learn more about thermoforming? There is a wealth of resources on the subject on our blog.

Have questions? You can also schedule a call with a Mayku specialist to make sure you’re on the right track. You can also get to know the Mayku Multiplier on its product page.