Discover how both technologies compare to each other, how they work, common materials, benefits and more

Previously, we have examined thermoforming technology as a whole, as well as vacuum forming and pressure forming as individual processes. Now, we’ll put the two side by side, comparing how the technologies work, common materials, benefits, and much more.

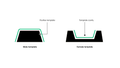

How vacuum forming works

Vacuum forming is the oldest method of thermoforming, and refers to the use of a vacuum to remove the air between heated plastic material and a template. The subsequent vacuum causes the plastic material to fully conform to a template, capturing details, shape, and other features.

First, a plastic material, typically in the form of a sheet or a roll, is loaded onto the vacuum machine’s material carrier, where it is heated from above.

Once sufficiently softened, the vacuum-forming tool is pulled closer to the template, creating a seal. After this, a vacuum pump creates a vacuum, drawing the sheet over the template in the vacuum-forming tool.

The resultant plastic cools and sets, then is removed by hand or with the use of air. If necessary, it can then be trimmed or otherwise modified to meet certain specifications.

How pressure forming works

Pressure forming refers to the process of using air pressure on a heated plastic sheet to create a mold or part. It is able to create parts or tools that exhibit high degrees of details and texture.

First, a plastic sheet is inserted into a pressure-forming machine so that it sits over a template. It is then heated from above. Once the proper temperature is reached, pressurized air pushes the plastic sheet over the template. An air vent removes any access air. Once sufficiently cooled and hardened, the plastic – now a mold – is removed from the template to be used as is or to be further processed.

Thermoforming materials

Vacuum forming and pressure forming are compatible with the same materials, although pressure forming is usually capable of using thicker plastic sheets than vacuum forming – resulting in thicker end parts.

Here are some of the thermoforming materials compatible with the Mayku Multiplier.

- HIPS (High-impact polystyrene) – stable, low cost, and impact resistant

- EVA (ethylene-vinyl acetate) – featuring low-temperature toughness and UV resistance

- PETG (polyethylene terephthalate glycol) – good hardness, chemical resistance, impact resistance, transparency and ductility, making it suitable for food-grade tools or parts

- PMMA (polymethyl methacrylate) – optical clarity, high resistance to UV light, good stiffness and abrasion resistance

- ABS (acrylonitrile butadiene styrene) – high stiffness, easy to process, good impact and chemical resistance

- UHMW (ultra-high molecular weight polyethylene) – ultra low friction, high impact resistance and strength

Other materials used for pressure forming and vacuum forming include:

- Polycarbonate (PC)

- Polyethylene (PE)

- Polypropylene (PP)

- Polystyrene (PS)

- Polyvinyl chloride (PVC)

- Low-density polyethylene (LDPE)

- And many more

Learn more with our comprehensive guide on thermoforming materials.

Thermoforming templates

Vacuum forming templates

In vacuum forming, male templates are more common, as the materials used are typically thinner, and the level of detail expected on applications such as packaging is not as high.

Pressure forming templates

In pressure forming, female templates are most common, as molds or parts with high levels of detail, texture or other exterior aesthetics are often created using the process.

For more on the differences between vacuum forming and pressure forming, you can read our articles on the basics of vacuum forming and pressure forming.

Technology benefits

Discover the difference between pressure forming and vacuum forming in the table below.

Affordability. Small production runs often cheaper than injection molding, due to lower tooling cost.

Speed. The creation process is often faster than other manufacturing methods.

Flexibility. Test and iterate quickly and cost-effectively.

Toughness and durability. Compatible with materials that offer great mechanical properties.

Consistency. Very little variation between individual parts.

Food-safe materials. Viable manufacturing method for food-safe containers.

Level of detail. The parts and molds are able to capture small details such as text or textures (less than <1μm)

Precise part tolerances. The parts made offer precise tolerances when using female molds.

Surface finish. The parts and molds made capture the template’s exact surface finish

Material thickness. Up to 5mm material thickness.

Mayku 3D formers

Mayku FormBox: Desktop vacuum 3D forming machine

The Mayku FormBox is a compact, vacuum-powered 3D former – and is part of Mayku’s 3D former family. A 3D former is powered by technologies such as thermoforming, and is as easy to use as a desktop 3D printer.

The Mayku FormBox is compatible with multiple materials, including those which are flexible and resin-resistant. It uses a 1000W ceramic heater to heat a plastic forming sheet that can be molded onto a template object. Once the sheet has been heated and lowered onto the template, suction forces the heated sheet into every detail of your part, tool, or object.

Mayku Multiplier: Benchtop pressure forming machine

The Mayku Multiplier is a desktop 3D former powered by industrial pressure forming technology. It’s compatible with multiple plastic types and thicknesses, and results in highly detailed final parts and molds. When filled with compressed air, the Multiplier’s dome is pressurized to four atmospheres. This pressure forces air onto a heated plastic sheet into every crevice of a mold, and is able to capture details of less than <1μm with materials such as EVA sheets.

Main takeaways

Overall, desktop vacuum and pressure forming are both excellent technologies for creating custom parts and components. Vacuum forming is usually a cost-effective solution, offering great flexibility for parts with lower accuracy and detail needs. Pressure forming, on the other hand, is better suited for parts that require high detail and dimensional accuracy, superior mechanical properties, and tight tolerances.

Get started with thermoforming

Want to learn more about thermoforming? There is a wealth of resources on the subject on our blog. Have questions? You can also schedule a call with a Mayku specialist to make sure you’re on the right track. You can also get to know Mayku 3D formers on our product pages.