Discover the best ways to manufacture thermoforming templates and their main advantages

Successful thermoforming heavily depends on a template that is well-suited to the task at hand. Templates themselves, however, will differ depending on the manufacturing method used to create them. In this article, we’ll take a look at several popular manufacturing methods – such as 3D printing technologies – that can be used to create thermoforming templates, as well as a few points to consider about each.

Additive manufacturing

Additive manufacturing, also known as 3D printing, is the process of creating a 3D object from a digital model. It is done layer by layer – hence “additive” – typically with a material such as plastic, resin, or powder.

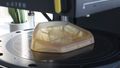

FDM 3D Printing (Filament)

Fused Deposition Modeling (FDM) 3D Printing is an additive manufacturing technology in which layers of materials are fused together. The material – in the form of plastic or composite filament – is first heated, then extruded following a pattern, creating objects layer by layer.

Here are a few points to consider when using FDM 3D printing to create a thermoforming template:

- Affordability. FDM 3D printing is one of the most affordable manufacturing technologies. A wide range of 3D printers and materials available are compatible with the Mayku Multiplier and FormBox, from entry-level to industrial-grade.

- Ease of use. FDM 3D printing is a clean manufacturing process that generates almost no waste. You can remove prints from the 3D printer with your hands once they're ready. No post-processing is required unless you want to remove support materials or smooth the surface.

- Visible surface texture. Due to the manufacturing process itself, all 3D printed parts have a unique, layered surface texture.

- Limited feature size. Most FDM 3D printers feature a 0.4 mm nozzle. No template feature such as text or surface details will be visible if they're smaller than 0.4 mm.

Want to learn more about creating thermoforming templates with FDM 3D printing? Check out our article on making thermoforming templates with FDM 3D Printing.

SLA 3D Printing (Resin)

Stereolithography (SLA) 3D printing, or resin 3D printing, is an additive manufacturing technology in which a light source – typically a laser or projector – cures liquid resin into hardened plastic.

Here are a few points to consider when using SLA 3D printing to create a thermoforming template:

- Level of detail. Templates made with resin 3D printers can exhibit incredibly small details such as text, logos, and unique textures.

- Surface finish. Because resin 3D printers can achieve precise results, you can more accurately control the surface texture of printed parts – including smooth, clean surfaces.

- Post-processing. All resin 3D printed parts must be post-processing. This is typically accomplished by rinsing finished parts in isopropyl alcohol (IPA) to remove uncured resin from their surface, then curing using UV light to reach the highest possible strength.

- Complex geometries. The efficient use of support material allows you to create complex designs without additional post-processing or template modification.

Want to learn more about creating thermoforming templates with SLA 3D printing? Check out our article on making thermoforming templates with SLA 3D Printing.

SLS 3D Printing (Powder)

In selective laser sintering (SLS) 3D printing, a laser sinters polymer powder into a solid, three-dimensional object. Here are a few points to consider when using SLS 3D printing to create a thermoforming template.

Here are a few points to consider when using SLS 3D printing to create a thermoforming template:

- Great material properties. The nylon powder used in SLS gives printed parts excellent mechanical properties and temperature resistance, making them ideal for thermoforming.

- High levels of detail. SLS allows for a high level of detail, making it convenient for specific thermoforming applications.

- Textured surfaces. All SLS 3D printed parts have a grainy surface finish, although the layer lines are almost invisible. Templates can be post-processed to be smoother.

- Cost. SLS 3D printers are expensive – and so are consumables and post-processing stations. Because of this, parts created with SLS are usually outsourced.

- No need for airholes. SLS parts are usually porous, which means air holes are not necessary on certain template designs. Air can instead be evacuated through the part itself.

Want to learn more about creating thermoforming templates with SLS 3D printing? Check out our article on making thermoforming templates with SLS 3D Printing.

Subtractive manufacturing

Whereas additive manufacturing places layers of materials on top of one another – whether it’s via FDM, SLA, or SLS 3D printing – subtractive manufacturing starts with a solid block of a particular material, then removes pieces or areas to arrive at a final shape.

Laser cutting

Laser cutting is a digital fabrication process in which a laser is used to cut through flat materials by vaporizing, burning or melting them, leaving an edge with a high-quality surface finish.

Here are a few points to consider when using laser cutting to create a thermoforming template:

- Fast manufacturing. Laser cutting is the fastest manufacturing technique. You can make large templates in minutes, and no post-processing is usually required.

- Surface-etching details. Laser cutting machines not only cut, but also etch a material’s surface. This means you can easily add highly detailed text, logos, or unique textures to your templates.

- Accessible design process. Due to the flat nature of laser cutting, designing templates is quite simple. It can be done using graphic design software such as Adobe Illustrator or Inkscape.

- Only 2.5-D designs. Laser-cut templates are created by stacking different layers, each one with a unique shape. Templates are made by extruding 2D designs in one direction, creating a 2.5D template, which limits the shapes that can be created from them.

CNC machining

In Computer Numerical Control (CNC) machining, a computer-controlled CNC machine follows a coded program to process a material to meet certain specifications, typically through cutting or grinding, such as with a lathe.

Here are a few points to consider when using CNC machining to create a thermoforming template:

- High precision. Some CNC machines can produce fine tolerances needed specifically for thermoforming applications.

- Material availability. There are many types of materials compatible with CNC, including temperature-resistant polymers that are perfect for thermoforming templates.

- Large template size. CNC machining enables the creation of large templates that may be difficult to manufacture using 3D printing technologies.

- Cost. Complex thermoforming templates may require the use of a five-axis CNC machine, increasing the manufacturing cost. Because of this, manufacturing is usually outsourced.

Other methods of template manufacturing

Clay modeling

Clay modeling is just that – using clay to create a three-dimensional sculpture. Common types of clay used in modeling include oil-based clay, self-hardening clay, and ceramic or pottery clay.

Here are a few points to consider when using clay modeling to create a thermoforming template:

- Accessibility. Clay doesn’t require any specific machines and can be purchased relatively cheaply and easily, meaning it’s easy to integrate clay into your thermoforming workflow.

- Speed. Using clay is usually a relatively quick process, making it one of the best template-creating methods for educational environments.

- Limited uses. Clay is only recommended for desktop vacuum forming machines such as the Mayku FormBox. Templates created with clay can easily deteriorate or break if used with industrial thermoforming machines.

- Limited customization. With clay, it is more difficult to follow thermoforming design principles, as you can’t easily set wall inclination or air hole size. This is why clay templates are recommended only for small objects, and may require more testing than those created with other forms of manufacturing.

Learn more about clay templates with our guide on How to design a mold using polymer clay with Adele Morse.

Using real objects

Sometimes real objects can be used to create a thermoforming template. Here are a few points to consider when doing so

- Convenience. Using real objects to create a thermoforming template can be convenient – and in some cases ideal – such as those scenarios when you want to make a mold of an existing object to make a chocolate replica.

- Risk of damage. Fragile or soft objects aren’t recommended as they can easily be damaged during the forming process.

- Design limitations. Thermoforming best practices must still be followed when using real objects, which means most objects can’t be easily used as thermoforming templates.

In general, using real objects as thermoforming templates is not recommended. It is usually best to reverse engineer an object’s design to create a 3D model, which can be modified to meet your specifications and then 3D printed, so that it looks similar, but it follows the fundamental design principles of thermoforming.

Take template creation to the next level

A quality template can mean the difference between a successful and unsuccessful thermoforming experience. This means you should go into template design and creation with the knowledge you need to adhere to the best practices of thermoforming.

You might want to get started with learning the basics of the thermoforming process. For that, you can read our article on what is thermoforming. If you’re ready to get started with thermoforming, you can always explore Mayku’s 3D formers, which are suitable for both vacuum forming and pressure forming processes.