EVA

Produce flexible, shock absorbent parts that are easy to recycle.

EVA

EVA stands for Ethylene Vinyl Acetate, and is known for its flexibility, durability, and lightweight properties. EVA is a non-toxic material, making it safe for use in consumer products such as shoes, toys, and even food packaging. EVA is increasingly popular in many different industries because it is easy to process and recycle, making it more environmentally friendly than other plastics.

Key properties:

Shock absorbent capabilities

Insulating and waterproofing properties

Easy to process and recycle

Excellent flexibility

Good strength

Tear resistant

Lightweight

Non-toxic

Resistant to water, UV radiation, and chemicals

Ultra high detail

Useful for:

Protective packaging

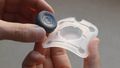

2-part molds

Shoe soles and insoles

Hot melt adhesives

Pressure-sensitive tapes

Toys

Button shrouds

1.5mm

$12.50

Download important documents

Reasons to choose EVA for your application:

- Lightweight

- Excellent shock absorption capabilities

- UV resistant

- Good thermal insulation properties

- Excellent flexibility

- Easy to de-mold

- Water resistant

- Chemical resistant

- Non-toxic

Application

See how EVA was used to create a flexible 2-part mold

Browse other materials

PETG

Prototype food-safe packaging and create transparent parts in minutes.

ABS

Produce tough, impact-resistant parts with excellent surface appearance.

UHMW

Produce strong, abrasion-resistant parts with a low friction coefficient.

Book a call

Let's chat about possible applications or any other ideas or questions you might have. Book a call with a member of our team below.

Find a timeSubmit a question

Want to know more? Send us a question and we’ll get back to you as soon as we can.

Ask nowFind a reseller

Our certified resellers have invaluable application and workflow knowledge. Connect with a reseller near you.

Connect