Motorsports protective gear using UHMW

26 mins

1d 20 hrs

Application overview

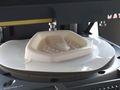

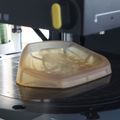

Prototyping motorsports protective gear with the Mayku Multiplier

Prototype protective gear that is durable, lightweight, and has a low friction coefficient using the Mayku Multiplier and UHMW. This makes it ideal for scenarios where material properties are critical during prototyping and testing. The parts can withstand wear and tear, and can be produced quickly and cost-effectively in-house. This makes it an ideal choice for businesses that need to prototype protective gear quickly and efficiently.

The key benefits of using the Multiplier:

- Take full control of the prototyping and testing

- Test complex parts and intricate designs

- Customize the prototypes and make parts that meet specific requirements

- Reduce out-sourcing costs and lead time

- Reduced tooling costs due to the elimination of the need for expensive molds

- Use validated engineering materials when testing

Application considerations

There are some key considerations when prototyping

Template design

We recommend using 0.75mm air holes, draft angles of at least 8º on all sides, and using a female mold for maximum detail

Template manufacturing

Manufacturing the templates with SLA 3D printing offers great flexibility and template quality for short production runs

Template finishing

The Multiplier picks up all texture, so it’s recommended to clean up every detail in post-processing.

Choosing UHMW material

Use UHMW if your application requires low-friction, high strength or impact, chemical and abrasion resistance.

UHMW template removal

due to the material’s low friction, removing the template is easier than other materials like PETG or PMMA.

UHMW part cutting

Use a hot knife or kevlar scissors for small runs, and automate with a CNC machine for large runs.

Find out more about the Mayku Multiplier

Talk to us for pricing

Get the most out of 3D forming for your application

Creating thermoforming templates with SLS 3D printing

Template design & creation • 5 minutes read • 23rd Mar 2023

Creating thermoforming templates with FDM 3D printing

Template design & creation • 6 minutes read • 23rd Mar 2023

Thermoforming and 3D printing

Template design & creation • 5 minutes read • 23rd Dec 2022

Book a call

Let's chat about possible applications or any other ideas or questions you might have. Book a call with a member of our team below.

Find a timeSubmit a question

Want to know more? Send us a question and we’ll get back to you as soon as we can.

Ask nowFind a reseller

Our certified resellers have invaluable application and workflow knowledge. Connect with a reseller near you.

Connect